The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Discussing

Table of ContentsMotorcycle Parts New Zealand Specialists Things To Know Before You Get ThisThe 8-Second Trick For Motorcycle Parts New Zealand SpecialistsFascination About Motorcycle Parts New Zealand SpecialistsSome Known Details About Motorcycle Parts New Zealand Specialists Rumored Buzz on Motorcycle Parts New Zealand SpecialistsWhat Does Motorcycle Parts New Zealand Specialists Do?The Greatest Guide To Motorcycle Parts New Zealand SpecialistsThe Best Guide To Motorcycle Parts New Zealand Specialists

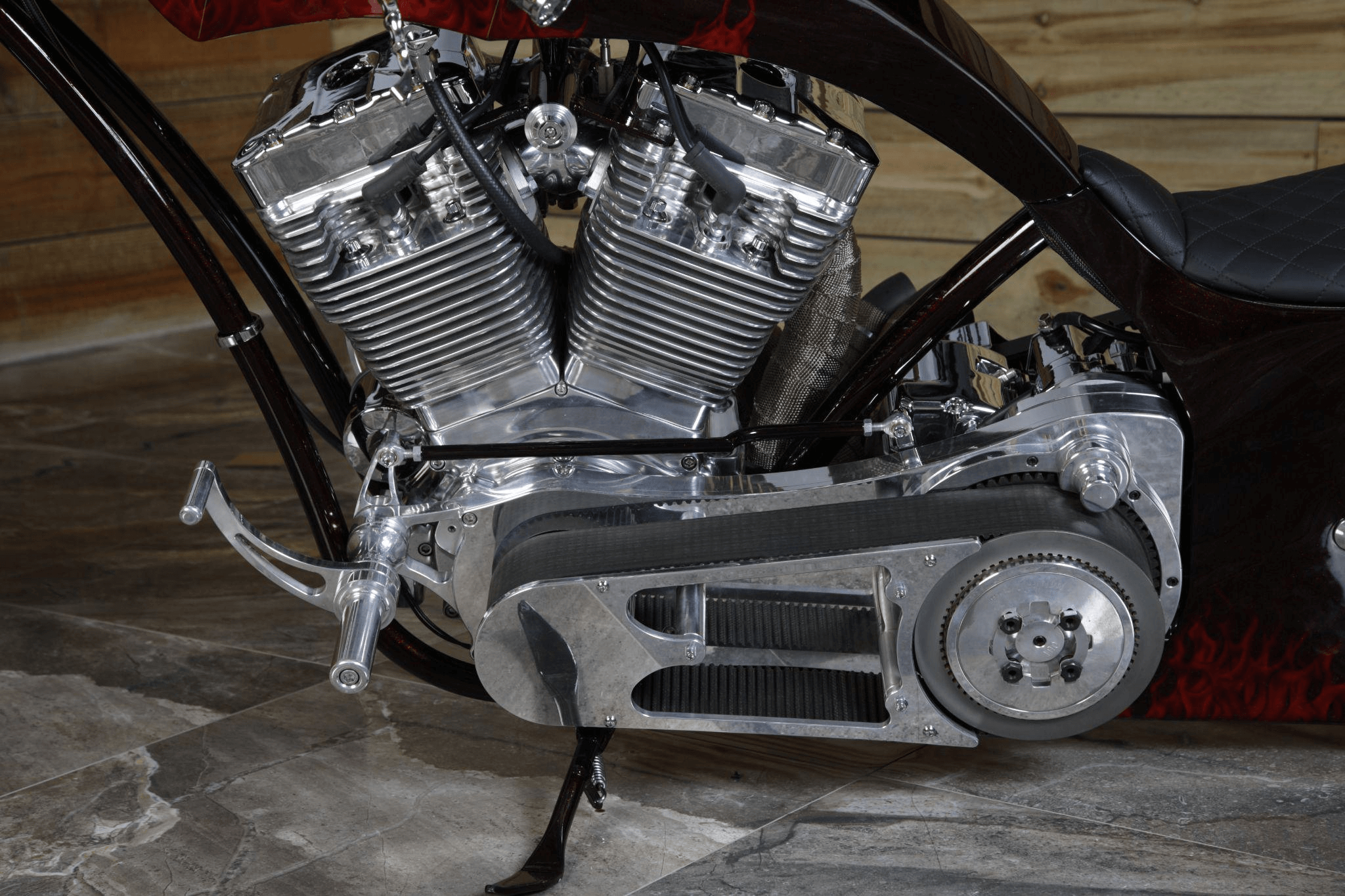

So, connect to one of our specialists today.CNC machining technology is swiftly becoming the centerpiece of lots of various production processes around the globe as a straight result of its numerous advantages over other approaches. In addition, the industries that make bikes have actually gotten on board with this fad. The most innovative business are now establishing their engine components and wheels making use of machining methods initially developed for motorbike components.

You might be questioning why we use. Currently that we have your attention let us clarify the reasoning behind this contemporary growth in the bike production market.

The Best Strategy To Use For Motorcycle Parts New Zealand Specialists

In addition, you have complete control over the appearance of the components, even down to the min details. Periodically, motorcyclists may decide to improve their trip by mounting aftermarket parts or modifying the bike's remodeling. Once again, computer system numerical control (CNC) machining is the most functional approach. Upgrades may be of any type and design you desire.

Some Known Details About Motorcycle Parts New Zealand Specialists

CNC machining might be utilized to make virtually all of a bike's metal and plastic elements. To continue, we'll discuss numerous machined parts for bikes.

Milling procedures are used to get the wanted degree of wheel modification. One more element of the motorbike that might be individualized is the tires.

The Best Guide To Motorcycle Parts New Zealand Specialists

When it comes to a lorry (or a motorcycle), one of the most crucial element is the engine. Several people suggest to it as the "heart" of the car. On the other hand, the camshaft, the cylinder head, and the pistons tend to be intricate and need designs with a high degree of accuracy.

Lighting is one more complicated aspect of personalization. Use only top quality things, however, because these lights are critical for the safety of motorcyclists and other chauffeurs or people when traveling, specifically at evening. Motorcycle fronts lights have 3 primary components: the light bulb, or source of light, the lens, and the real estate. Particularly, we customize the lens and the real Get More Info estate.

Milling processes anonymous with a flawless finish would certainly lead to the lenses having a reflective high quality that resembles that of a mirror. The cover, on the various other hand, is not made up of fragile products; rather, it is constructed out of challenging polymers that can be machined into more intricate patterns.

The Ultimate Guide To Motorcycle Parts New Zealand Specialists

Motorcycle suppliers usually cast these components, yet only for the production of bespoke components. Machining on five axes in today's globe is the means by which any style shape may be recognized.

Pick Runsom for your tailored bike parts! We have the capability to produce challenging and trendy elements making your motorbike unparalleled.

Below are a couple of instances of steels often utilized in motorcycle component machining. Light weight aluminum is the key material made use of by companies specializing in creating personalized bike elements to develop a lot of these components. In the past, we would construct our engines out of actors iron. On the various other hand, light weight aluminum is quickly coming to be the material of option, partly as a result of the reality that it is extra lightweight.

Zinc describes an additional steel that is really light in weight and has fantastic machining qualities because of its high mechanical strength. This material might be developed into virtually any type of form and preserves its measurements well. Also mission-critical components that require a high degree of accuracy may take advantage of their use.

Examine This Report on Motorcycle Parts New Zealand Specialists

One more steel that sees hefty use in the manufacturing of CNC-customized parts is magnesium. It is amongst the lightest steels that are now obtainable and Going Here has outstanding machinability features and stamina proportionate with its reduced weight. Among the disadvantages of magnesium is that its dust may easily ignite.

Their most common use in producing various motorcycle components is fasteners, such as screws and screws. Their reduced sensitivity to oxidation and rust makes them suitable for this use.

The Motorcycle Parts New Zealand Specialists PDFs

It appears that CNC turning and milling are the foundational processes. In addition, it calls for keeping bars of material, most typically plastic or metal, in position and then turning a reducing device to remove sections of the product as the product is transformed.

These techniques are equally important and produce components with high precision and constant top quality. They are respectively: grinding, laser cutting, and boring. The term "surface area finish" refers to post-processes after the preliminary machining phase. Motorcycle Parts New Zealand Specialists. The processes aid enhance the overall top quality of the machined bike components. Below are the brief introduction, advantages and disadvantages of 5 surface treatment techniques.

The Basic Principles Of Motorcycle Parts New Zealand Specialists